“One-Day Polyurea” Coating Systems: Speed and Quality Don’t Correlate

What’s the truth about one day systems? Concrete coatings are rapidly gaining in popularity. This trend has led to a surge in the number of new concrete coating businesses seeking to capitalize on the mounting interest. Many have leaped onto the “1-day polyurea” or “1-day polyaspartic” wagon, lured by customers’ desire for speedy 1-day installations. To achieve a one day installation, however, these contractors use fast-curing coating products (called polyureas or polyaspartics). But as GarageFloorCoating.com highlighted in their August 2020 piece titled “Polyurea-Polyaspartic One-Day Systems: Do They Work“, speed and quality don’t correlate in the world of concrete coatings. How would they know? GarageFloorCoating.com has been installing concrete coatings since 1996, and its network of dealers, including us, has installed over 70 million square feet of concrete coatings!

The Difference Between a Polyurea & Polyaspartic Coating

Contractors who install concrete coating systems in a single day use products known as “polyureas” or “polyaspartics”…and they use them as both the primer coat and subsequent transparent top coat. This is a critical point as to why these coatings are problematic. When selling these systems to customers, the “1-day” contractor often emphasizes how technologically advanced their product is, with its quick-curing properties and extreme UV, chemical/stain and impact resistance. All true. Because they only use polyurea (or polyaspartics) in their arsenal, they also tend to “trash talk” other coating types like epoxies. This is convenient misinformation.

To understand this story, let’s start with the difference between a polyurea and polyaspartic. They are chemically different…but a polyaspartic is simply a polyurea (an aliphatic polyurea…for the chemistry nerds) modified to slow down its cure rate. And this is necessary to allow the applicators time to apply the product with rollers and/or squeegees. That is, polyaspartics are simply more user-friendly. They’re slowed-down polyureas…but still considered fast-cure products (the waiting time between coats can be as low as 1-2 hours).

The Cons of Using a Polyurea-Polyaspartic as a Primer Coat

But here’s the catch! By the nature in which a polyaspartic (or aliphatic polyurea if you like) cures, these coatings cannot be applied thickly to concrete; they only allow for thin to moderate film builds. And due to their fast-curing properties, they just don’t penetrate concrete well. They’re simply not designed for direct-to-concrete application…just ask an architect (or ChatGPT)…especially concrete that has medium to high moisture content.

All concrete is exposed to some moisture. It wicks up from the soil through the porous concrete in a process called “moisture-vapor transmission”. Over time, hydrostatic pressures can build to the point where the thinly applied polyurea-polyaspartic coatings have a tendency to delaminate. Which is why no “1-day” contractor will fully warrant their coatings against “moisture-related issues” or “high hydrostatic pressures”…just read their warranty exclusions on their own websites! So fast-curing, “1-day” coating systems seem attractive at first glance, but there are definite problems.

If this was not the case, wouldn’t these contractors fully warrant their coatings?

Cue the Epoxy Primer

Epoxies cure by way of an exothermic reaction (heat is created). Unlike a polyurea-polyaspartic, these products cure in such a manner that “the greater the mass” (the thicker it is), the faster it cures. This is why when a 2-part epoxy is mixed in a container, you need to get it out onto the floor quickly…because it’ll “cook” in the container. But this very property allows epoxies to be applied thickly…they’re called “high-build” coatings. And this thick coating is far more effective at withstanding high hydrostatic pressures. Architects know this, as do honest contractors, which is why they’d never, ever recommend or apply a polyurea-polyaspartic as a primer coat, direct-to-concrete.

Although epoxies are better primer coats, especially under high-moisture conditions, than a polyurea or polyaspartic, they have their own limitations. Epoxies have low UV resistance and tend to amber or chalk over time if exposed to sunlight. So this low UV resistance and moderate chemical resistance makes them poor topcoats!

But what if you used both products in your coating system…using the best properties of each product type to build the most durable coating system possible? That is, what if you used an epoxy as the primer coat, then covered it in a layer of flakes (so as not to expose it to UV light and chemicals), and topped it all off with a polyaspartic coat to provide the needed UV and chemical resistance?

This is Exactly What We do to Create Our Coating Systems

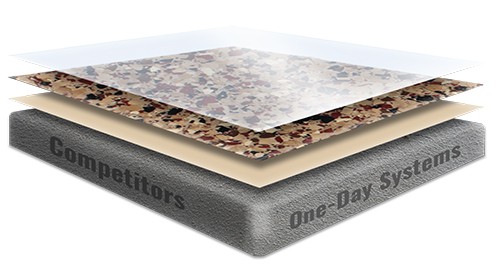

“1-day” coating systems consist of 3 layers: (a) a thin direct-to-concrete primer layer of polyurea-polyaspartic; (b) a full-flake layer comprised of thermoplastic flakes only, and (c) a single clear top-coat of polyaspartic – all applied swiftly to meet the “1-day” installation requirement. Albeit, the final system is wafer-thin and susceptible to delamination.

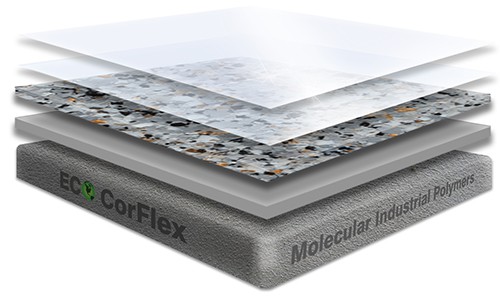

Conversely, our coating systems combine the best properties of both epoxies and polyaspartics. We apply our 100%-solids, moisture-mitigating epoxy as the primer coat (layer 1), cover it with your choice of thermoplastic or mica-mineral flake blends (layer 2), and top it all off with 2 coats, not 1, of our clear 100%-solids polyaspartic (layers 3 and 4) for a 4-layered, 35 mil+ thick coating. Because we use an epoxy as the primer coat (with its slower cure rate), our installation duration is 2 days, not 1. But this is a good thing! It produces a superior coating system with significantly less chance of delamination. This is why we can provide a real guarantee…one that warrants against all moisture-related issues.

Beyond the Standard

Our flooring is simply far beyond the standard of “1-day” systems. We use industrial-grade, 100%-solids products. We prime our floors using our proprietary, moisture-mitigating epoxy. We offer over 30 mica-infused flake blends (not just thermoplastic options)…and we top all our full-flake garage floor coatings with 2 separate coats of polyaspartic (not just one)…for extremely resilient full-flake flooring, guaranteed against any moisture-related issues or hot-tire transfer for 15 years. Something the “1-day” guys just can’t do. (They do provide seemingly long guarantees, but include warranty exclusions to “moisture-related issues”…so when your floor peels, they invoke the exclusion. It’s a guarantee that’s not worth the paper it’s written on).

Avoid the “1-day” temptation and call us today at (615)-878-4320 for your free estimate. We’re your local, expert installers of industrial-grade concrete floor coatings.

Ours

Theirs