In the world of garage flooring, knowledge is power. When you understand the terminology, you can spot red flags, ask the questions that matter, and avoid paying for a system that won’t hold up to Great Lakes winters or daily vehicle use. Here are the key terms every smart buyer should know before signing a contract.

Epoxy Coatings

Epoxy is the foundation of a durable system—a two-part material that cures into a thick, extremely adhesive layer. Pros use moisture-mitigating epoxy for primers and broadcast coats because it slowly cures and deeply penetrates the concrete. If an installer downplays epoxy or tries to replace it with a single “all-in-one” product, that’s a sign they’re cutting corners.

Moisture Mitigation

Concrete constantly emits moisture vapor, especially in regions with snowmelt and seasonal moisture like the Great Lakes. Moisture mitigation means applying a moisture-mitigating epoxy primer that forms a vapor barrier. Without it, coatings can peel or delaminate. Reputable 2-day installers include this step; bargain 1-day systems frequently skip it to save time.

Concrete Paint

Paint is inexpensive—and installers selling low-cost options often hope you won’t know the difference. Concrete paint does not bond chemically with the surface and cannot handle hot tires, moisture, or winter runoff. If a company uses “paint” and “coating” interchangeably, that’s a major warning sign.

Polyaspartic

Polyaspartic is a professional-grade clear topcoat prized for its UV stability, fast cure time, and chemical resistance. It protects the flakes and epoxy beneath it. Honest installers will tell you polyaspartic is a topcoat—not a replacement for epoxy or moisture mitigation. If a contractor sells an “all-polyaspartic system,” ask what they’re using for the primer (and brace for a vague answer).

Polyurethane

A clear coat option sometimes used in flooring systems. While durable, polyurethane typically underperforms compared to polyaspartic in UV and chemical resistance. If longevity and clarity matter, polyaspartic is the smarter investment.

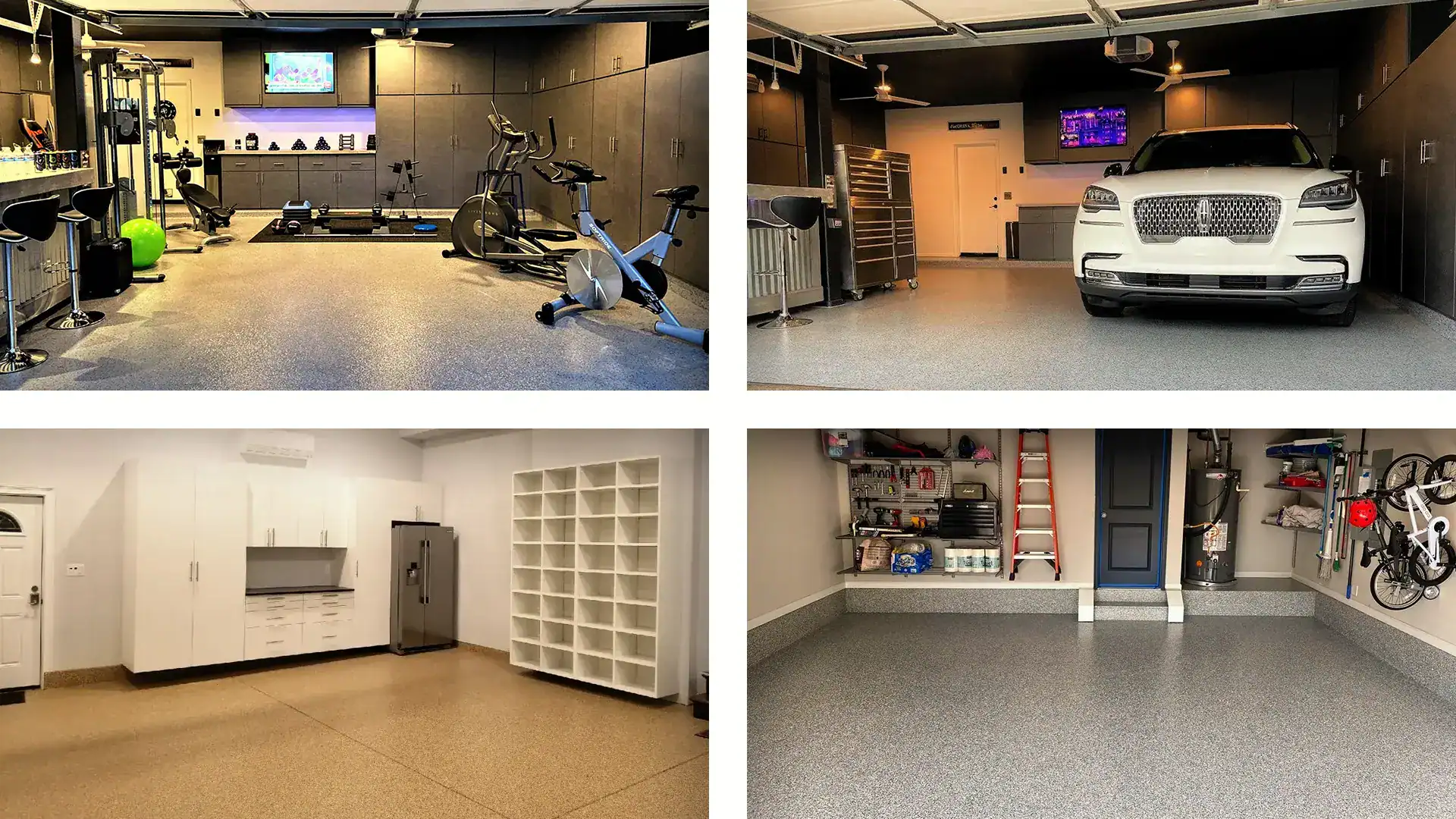

Flake/Full-Flake

In a flake epoxy system, colored polyvinyl acetate (PVA thermoplastic) and/or mica mineral flakes are broadcast into wet epoxy to add traction, color, and depth. A full-flake floor completely covers the surface, creating a thicker, more uniform finish that holds up to heavy use and Midwest weather.

Garage Floor Coating

A true garage floor coating is a multi-layer system: moisture-mitigating epoxy primer, full-flake coverage, and a polyaspartic topcoat. When installers skip any of these steps, you’re not getting the durability you’re paying for.

Want garage flooring you can trust, and a contractor who’s transparent about every layer? Garage Floor Coating – The Great Lakes installs high-performance systems designed for long-term durability. Request your free quote today.